Predicting the underwater noise produced by a ship is becoming more and more important in the shipbuilding industry. Ships have to comply with increasingly strict international requirements regarding underwater noise. The quieter the ship, the better, say Maarten de Boer and Izak Goedbloed from Damen Naval. “Just like CO2, underwater noise is also an emission that must be reduced.” Damen Naval’s performance in reducing underwater noise on its ships is exceptional. Maarten and Izak say that the company has made great strides on this subject in recent years. They are both specialists in underwater sound; Maarten as Lead Engineer of the Shock & Noise Team of Research & Technology Support and Izak as Principal Engineer Structures within the Structural Analysis team of Engineering.

Maarten and Izak on board the RSV Nuyina

Maarten and Izak on board the RSV Nuyina

Izak is taking part in DCR-Pursuit: a Damen-wide project to make new-build ships quieter. Maarten ensures that ships are designed and built to meet international underwater noise requirements such as ICES 209, Silent-R or military requirements. “Scientific research vessels, for example, must meet such low-frequency noise requirements in order to affect marine life as little as possible and not to disturb or scare away fish,” says Maarten. “Because if you want to research fish stocks as accurately as possible, you obviously shouldn’t scare those fish away.”

On-board equipment used for research must therefore not make too much noise, and the high-frequency noise produced by the ship itself must also be kept within certain limits, says Maarten.

“A ship should not be so noisy that the sonar equipment doesn’t work properly.” Underwater noise is a topical issue, and it is gaining more and more international attention. This is understandable because it is also a form of environmental pollution. In Damen’s DCR-Pursuit (Prediction of Underwater Radiated Sound Using Inventive Technologies) project, around ten specialists from various Damen companies work together to predict underwater sound more accurately.

They have made a 2 x 1 metre scale setup to perform calculations on Ship Transfer Functions using a Finite Element Model (FEM). The measurements were carried out in an acoustically silent test tank at TNO. “We validated those measurements under controlled conditions with calculations, and the results were surprisingly good,” says Izak. “This allowed us to develop a calculation method that makes it possible to predict those Ship Transfer Functions – the path of the sound of the ship to a receiver in the water – even better.

Dry impact hammer measurements in anechoic room to determine natural frequencies, mode shapes and transfer functions of the steel-construction.

Dry impact hammer measurements in anechoic room to determine natural frequencies, mode shapes and transfer functions of the steel-construction.

“The more accurate the predictions, the smaller the risks to your project and business will eventually become. And then in the proposal process, we as a shipbuilder can then meet the client’s needs even better. You can not only have safer contractual boundaries, but you can also work within narrower margins in your ship design.” Izak is one of the initiators of DCR-Pursuit, which has been running for two and a half years. The project is going so well that the next steps will be taken at full scale: on a real ship. “The results of this research will be compared with the measurement data already available.”

At the time when Damen Naval still worked mainly for the Royal Netherlands Navy, the Navy itself formulated the requirements for underwater noise. They did this in cooperation with TNO. “We did not get to see the results,” says Maarten. “But Damen Naval is now building naval ships and research vessels for other clients too. And since the construction of the first SIGMAs, specialists from Damen Naval have been intensely involved in predicting underwater noise levels by using all kinds of models in order to gain a clear insight into the dispersal of sound.”

“It is also necessary that ships become quieter for marine life"

The methodology has been further refined and Damen Naval is proud that, for a number of years now, the Damen Group has had its own mobile sound track with which underwater noise during sea trials at any desired location can be measured.

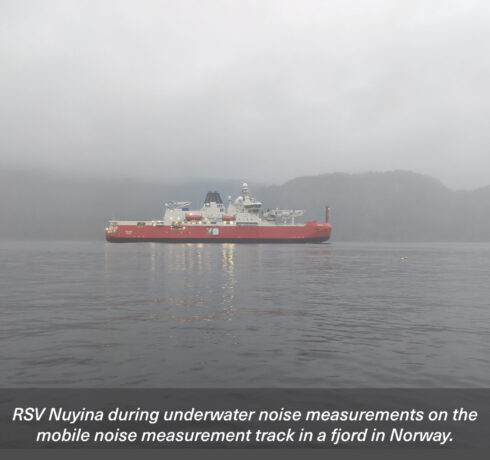

The first ship measured on this track was the Indonesian Navy SIGMA frigate Raden Eddy Martadinata. The Angolan Fishery Research Vessel Baía Farta and the Australian icebreaker Nuyina were also measured with the help of this mobile measuring track. Maarten: “With the icebreaker, this meant that we could measure the underwater sound signature without delay in the nearest fjord in Norway, instead of having to wait for the next free ‘slot’ at the busy fixed measuring track in Heggernes.”

The Australian supply and research vessel RSV Nuyina (the icebreaker) during underwater noise measurements on the mobile noise measurement track in a fjord in Norway.

The Australian supply and research vessel RSV Nuyina (the icebreaker) during underwater noise measurements on the mobile noise measurement track in a fjord in Norway.

Maarten and Izak note with pride that, in terms of knowledge of underwater noise, Damen Shipyards Group now holds a leading position in (at least) the Dutch maritime sector. However, the direct measurement of the noise that a ship makes underwater still remains a challenge. Maarten: “There are so many sources of noise on board; you never know exactly which device makes which sound and how this sound moves through the construction. But we are now able to calculate more accurately the behaviour of the foundations of resiliently mounted equipment on which noisy equipment is installed.”

“With FEM we can calculate much better than before whether a foundation is sufficiently dynamically stiff. This is important because of the vibrations that noisy equipment emit towards the ship’s structure. The improved calculations help create a design that is optimally acoustic. In any case, this is very important for naval vessels because, in terms of detectability, they should emit as little noise as possible. However, this development is also extremely important for research vessels and cruise ships sailing in certain areas.”

Wet impact hammer measurements in anechoic tank with hydrophones to determine natural frequencies, mode shapes and transfer functions in the steel-construction and to the water.

Wet impact hammer measurements in anechoic tank with hydrophones to determine natural frequencies, mode shapes and transfer functions in the steel-construction and to the water.

“It is also necessary that ships become quieter for marine life,” adds Izak. “The sea is becoming noisier due to activities such as windmills, piling, and shipping. Underwater noise doubles every ten years and that is going to take its toll. Fish get lost because noise disrupts their natural navigation; they lose their natural orientation and their compass. That is why the IMO is right to come up with international regulations to tackle this subject.”