Approaching deadlines, great results and a lot of hard work: plenty of progress has been made on the projects, so there is a lot to read. Discover Project F.A.S.T.’s plans and read about the final touches for the Midlife Update and Appointed Maintenance of HNLMS Johan de Witt. See the arrival of the aluminium superstructure for superyacht YN 478 and check out the new model of the Colombia project.

Lots of activity despite long delivery times at project F.A.S.T.

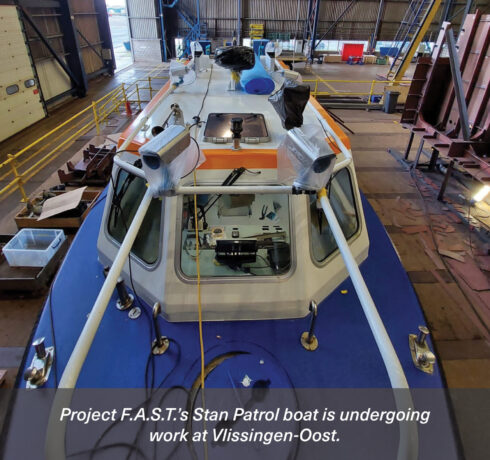

The conversion of the Stan Patrol 900 into an autonomous vessel has encountered some unexpected delays. Despite this, Jochem Nonhebel, Project Leader of the Fieldlab Autonomous Sailing Technology (F.A.S.T.) project, is optimistic.

The expectation was to install the electric motors as early as this winter, but delivery times are so long that they will now not be delivered until September 2023. In the meantime, the boat is undergoing a thorough refurbishment at Vlissingen-Oost. Jochem: “We are busy renewing the interior and the little boat is getting new windows.”

Comprehensive maintenance is needed as the boat was built in 1990. “This is also the year that I was born, which I really like,” Jochem laughs. “The Stan Patrol was built at Damen in Hardinxveld-Giessendam. That makes things easy because that means we own the drawings. Recently I even spoke to the person who had built the boat, which was cool!”

The interior of the Stan Patrol will be revamped and the boat will also get new windows.

The interior of the Stan Patrol will be revamped and the boat will also get new windows.

Last summer, the boat provided a ferry service in Vlissingen’s inner harbour; a pilot project that has now been completed. Jochem: “It was a learning experience, despite the business side of things being a bit disappointing. Due to low customer numbers, the revenue was not enough to operate the boat for whole days.” Regardless of these disappointing figures, sufficient data could be collected to optimise the software.

Besides Damen Naval’s own colleagues, several parties from the triple helix (a collaboration between government, educational institutes and industry) are working on the F.A.S.T. project. Jochem: “We have a fine cooperation with the education sector: HZ University of Applied Sciences and TU Delft. For instance, a group of students is developing automatic docking and mooring procedures.” In addition to this, Rotterdam-based startup CaptainAI is developing the software so that the boat can eventually sail autonomously.

What else is in the pipeline? Jochem: “In May, the boat will go back into the water and in June we hope to sail to SAIL Den Helder. Thanks to specially developed software, we know the best sailing route to Den Helder.” And after that? “We are far from finished, so that’s why we are already working on a new project proposal. We want to submit that for new subsidies so that we can continue the project in 2024,” Jochem concludes.

Project F.A.S.T. is funded by a grant from the European ERDF programme with the aim is to create an autonomously sailing ferry service between Vlissingen rail station and the city centre. There is now a dedicated LinkedIn page of the F.A.S.T. project and also a website: https://projectfast.nl/

Exciting times for the MLU project as the deadline is fast approaching.

Exciting times for the MLU project as the deadline is fast approaching.

Deadline approaches for Johan de Witt’s Midlife Update

On 31 March, work on the Midlife Update and Appointed Maintenance of HNLMS Johan de Witt must be completed. That means there is a lot of work to be done in a very short period of time, but Project Director Fer Tummers is optimistic. “Of course we will succeed in meeting the deadline,” he says.

Yet he is also aware that these are exciting times. “We have had some setbacks to process and there is still a lot of work to be done, so the pressure is increasing. The tricky thing is that at the moment everyone wants to finish their jobs and that means that sometimes several people want to work in the same space. So it’s a puzzle to keep everything running smoothly.”

Weather permitting, HNLMS Johan de Witt is expected to be towed to Den Helder on 1 April.

Weather permitting, HNLMS Johan de Witt is expected to be towed to Den Helder on 1 April.

With a team of about 250 people, they are pulling out all the stops to get everything completed on time. Two major items are now left on the agenda: the Harbour Acceptance Tests (HATs), the handover of (parts of) systems and, at the same time, the handover of all spaces on board to the customer. Fer: “A total of 62 HATs have to be carried out and there are 800 spaces to be handed over. After the final handover, they are cleaned and locked.”

Weather permitting, the Johan de Witt is expected to be towed to Den Helder on 1 April.

Colleagues from Damen Shiprepair Vlissingen helped to unload the aluminium superstructure for YN 478.

Colleagues from Damen Shiprepair Vlissingen helped to unload the aluminium superstructure for YN 478.

Aluminium superstructure YN 478 arrives at Vlissingen-Oost

The construction of the YN 478 hull by Damen Naval in Vlissingen-Oost has seen a lot of progress over the past few months. The project faced some unexpected challenges, but there were also successes, and the superyacht is starting to take shape.

The arrival of a new Damen Yachting refit project at Vlissingen-Oost means that the YN 478 project now has to share Hall 2. Initially the project used Hall 1 for section fabrication and Hall 2 for assembly, but over the past year some of the fabrication activities had gradually moved to Hall 2. The arrival of the refit means that the YN 478 now has to move all remaining fabrication activities to Hall 1. “We are currently facilitating this change – preparing the nearly completed sections for transport back to Hall 1,” says manufacturing coordinator Stan Haag. “Even though we have enough space in Hall 1, it requires good logistical planning to get all the sections back in place.”

The superstructure was built by Bloemsma Aluminiumbouw in Makkum.

The superstructure was built by Bloemsma Aluminiumbouw in Makkum.

There have also been some changes in the technical plans. “This has affected some sections that were already in the ‘sailing position’,” Stan explains. “Those now have to go back to ‘fabrication position’ to implement those technical changes.”

But YN 478 has also recently achieved an important milestone. “The ship’s aluminium superstructure was delivered on 3 February; that’s good news. The first thing we will do is take this section to the paint hall for a coat of primer. Then we will continue the work to prepare the superstructure for mounting on the steel hull,” Stan says. This superstructure was built by Bloemsma Aluminiumbouw in Makkum and the whole thing was transported to Vlissingen via inland waterways in week 5. Stan: “After arriving at Vlissingen-Oost, everything was successfully unloaded in cooperation with our colleagues at Damen Shiprepair Vlissingen.”

The superstructure was transported by boat on Dutch inland waterways.

The superstructure was transported by boat on Dutch inland waterways.

Another sign that the project is making progress is that outfitting teams of subcontractors have started working on the project’s HVAC and insulation work. “We have also started plans for the installation of equipment in the engine room,” Stan continues. “This includes all the heavy equipment such as gearboxes, switchboards, main engines and generators. The engine room is quite small; there is not much room to manoeuvre so this planning is very crucial.”

Despite the challenges, Stan points out that the atmosphere in the joint Damen Naval and Damen Yachting team remains good. “Everyone works together to find the solutions and to get the project finished. And, as my father-in-law says: ‘You can’t achieve a shine without some friction’.”

The second phase draft documents for the Colombia project are due to be delivered by 1 March.

The second phase draft documents for the Colombia project are due to be delivered by 1 March.

The Colombia project steams ahead

After the previous project update, there is once again a lot to report from the Colombia project. We catch up with Simon Delva, coordinator of the project and Engineer Products & Proposals (P&P) at Damen Naval. What’s more, during the conversation, we got a nice surprise…

Damen Naval signed a contract with COTECMAR in October 2022 for a design study in which Colombia is investigating a new generation of frigates. In November, the first package of reference ship documents was handed over to the client. Simon: “Cotecmar was impressed by the amount of data we provided.” The next deadline is approaching fast; the delivery of the second phase of design documents is scheduled for 1 March.

There is more to come in March: together with the client, a series of seakeeping model tests will follow at the Maritime Research Institute Netherlands (MARIN) in Wageningen. This will involve testing the ship’s movements in different sea conditions. “Here we will test a similar ship model in the water,” Simon explains. “We will measure the movement of the scale model in waves, for example, analyse this and make conclusions for the real ship from this. Afterwards, the results of the model tests will be compared with those of simulations to validate the calculation method. This will allow us to make better predictions in the future, where there is no need to do expensive model tests again.”

A ship model was created for the Colombia project to be used at trade fairs.

A ship model was created for the Colombia project to be used at trade fairs.

During the interview with Simon, we are suddenly surprised with a ‘special guest’. The brand-new ship model of the frigate is wheeled into the office. This model will be displayed at future exhibitions. Simon: “It has turned out very nicely. Now we just hope that we will soon also be asked to build the actual ship.”