Damen Naval delivered the Antarctic Supply Research Vessel Nuyina back in 2021. A lot has happened since then so here’s a look back at some key events, divided into the three broad chapters of the icebreaking trials, the end of Damen Naval’s warranty period, and the ongoing service being provided by Damen Australia.

1. Icebreaking Trials

The aim of the icebreaking trials was to verify how well the Nuyina could handle operations in Antarctic sea-ice conditions. The trials comprised the following tests: in particular the ship’s speed and manoeuvring in ice, but also mooring in ice, and range and endurance. Testing took place in Prydz Bay, Antarctica. This is close to Davis Station, one of three permanent research bases in Antarctica managed by the Australian Antarctic Division (AAD).

In the following excerpt from his report of the icebreaking trials, Gerry O’Doherty, the Master of the Nuyina, describes the conditions: “The sea-ice conditions were sub-optimal in terms of thickness of ice, with the depth of most of the sea-ice measuring less than the desired 1.65m. Conversely, the depth of snow was often greater than the 0.3m requirement. Snow greatly reduces an icebreaker’s capacity to break sea ice. In terms of testing icebreaking capability, any deficiency in the thickness of the ice was easily countered by the increased depth of snow.”

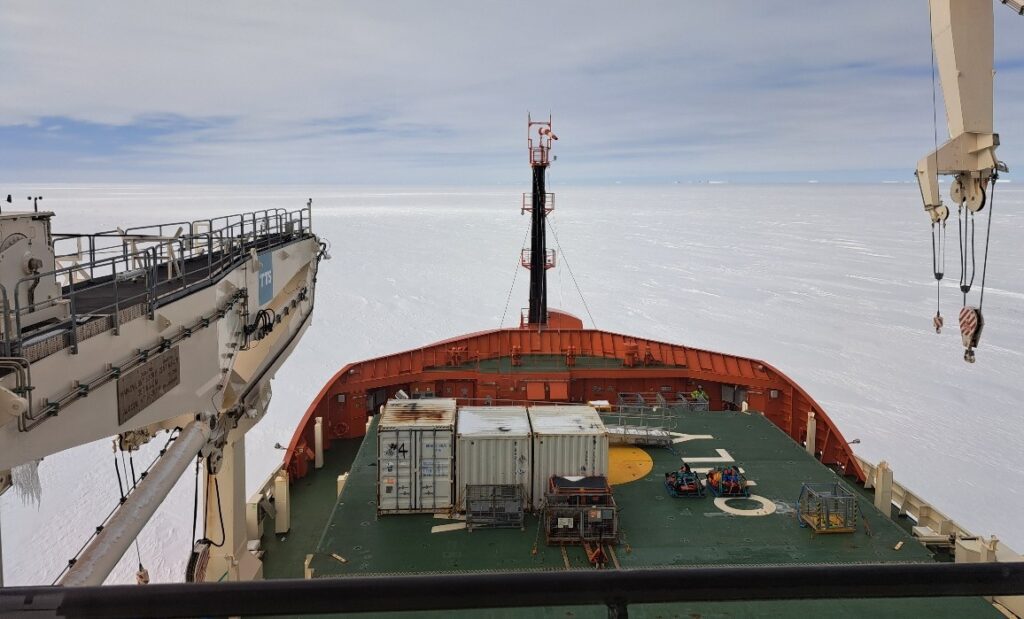

The view from the bridge as the Nuyina makes its way through the ice.

The view from the bridge as the Nuyina makes its way through the ice.

During the icebreaking trials, the ice characteristics were measured by a specialised team from the Hamburg Ship Model Basin (HSVA), assisted by Maikel Moerings from Damen Naval. HVSA was known to the project from its ice model testing during the design phase.

The results of the icebreaking trials were positive, according to Gerry O’Doherty’s report: “The effectiveness of the breakout manoeuvre, along with Nuyina’s good performance in a straight line, means that Nuyina is able to easily negotiate tight bends in heavy fast ice by a combination of these two features. Outside of the SST protocols, Nuyina was easily able to turn in heavy pack ice.” Gerry’s report concludes: “Nuyina has proved to be a very capable icebreaker, and I have every confidence she will safely take the AAP further into the Antarctic sea-ice than previously achieved.”

Check out the pictures of the icebreaking trials and measuring the ice characteristics below.

2. End of the warranty period

Damen Naval’s contracted warranty period for the icebreaker Nuyina came to a close at the end of 2024. After handling several warranty claims since delivery, Damen Naval’s Warranty Manager Michiel Schittekat had a few final points left on his list. “These related to specific scientific systems, some minor work on the AFC [clutches] and various parts that had to be delivered with longer lead times. One item – a new set of bridge windows – remained outstanding,” he says. The end of the warranty period “was a symbolic moment we were all looking forward to, celebrated with a few drinks by the local team”.

The icebreaking tests and outdoor activities, such as measuring the thickness of the ice layer, were easy to follow from the bridge.

The icebreaking tests and outdoor activities, such as measuring the thickness of the ice layer, were easy to follow from the bridge.

3. Ongoing service

Damen is still involved with the Nuyina, with continuing service being provided by our local colleagues in Damen Services in Australia. This service can be divided into three categories, continues Michiel. “First, there are the spare parts,” he says. “And then there’s additional engineering to upgrade numerous systems: LO storage, Praxis scope, gym area, searchlights, and echo sounder. We are also upgrading the refuelling system to include stern refuelling; at the moment, refuelling is only at the bow.”

Michiel Schittekat.

Michiel Schittekat.

The third aspect of ongoing service is an advisory role. “We give advice on a day-to-day operational basis; we assist any major repairs that are required – the stern tube, chilled water system rectification, and engine overhaul are examples of this. We are also setting up data for a dedicated Nuyina ship simulator.”

While the Damen Australia team coordinates this scope of service, with all the physical work being carried out in Hobart, Tasmania, both MEGA and Alewijnse “play a crucial role in engineering changes”, adds Michiel. “And finally, Nuyina is due for a maintenance docking in Singapore next year; the Damen Services team in Australia has been asked to make preparations for this.”