On 15 April 1998, the amphibious transport ship HNLMS Rotterdam was handed over to the Royal Netherlands Navy. The ship was built by the then Royal Schelde Group. Ben Angel remembers very clearly that less than a year later, the ship had to be modified under great time pressure to be deployed in the Kosovo war within the framework of Operation Allied Harbour. “It was a race against the clock, working day and night,” recalls Ben. As Project Leader, he had final responsibility for the scope of work.

Project Leader Ben Angel.

Project Leader Ben Angel.

“At the start of warranty maintenance on 12 March 1999, I took over Project Management from Sjaak Adriaanse,” says Ben. “The ship then returned to Vlissingen-East. It turned out that there were a lot of points that still had to be dealt with. ‘De Schelde’ also had to carry out a number of modifications to the ship. The whole job was supposed to take from 12 March to 17 May, but unfortunately the Kosovo war disrupted this planning. Already before the planned docking date, the Royal Netherlands Navy had requested to schedule the work in such a way that, if necessary, the Rotterdam could be ready to sail within four days. This was a great challenge for ‘De Schelde’ and its subcontractors.

It had been determined that the rear tailgate of the vessel was too short for deployment in the former Yugoslavia. “There were many sloping quays there. On such quays, the tailgate could not be fully lowered. On a vertical quayside, the ship can reach the quay, but on a sloping quay, the propellers get in the way. The stern had to be made three metres longer. This meant that part of the stern had to be welded off. In the meantime, new parts were made and welded in place. And the entire hatch with its hinge points had to be taken off in order to be put back in place later.”

Amphibious transport ship HNLMS Rotterdam was handed over to the Royal Netherlands Navy on 15 April 1998 and modified less than a year later.

Amphibious transport ship HNLMS Rotterdam was handed over to the Royal Netherlands Navy on 15 April 1998 and modified less than a year later.

Ben: “At about the same time, ‘De Schelde’ had taken on an order for the overhaul of a superyacht, the Boadicea, a job that took just about all of our staff and, for the work on HNLMS Rotterdam, we had to have welders flown in from Portugal. I remember that we worked very long days, we worked 24 hours a day on board in shifts; the time pressure was enormous. We did a lot of work in a short time with a relatively small team, but in the end we succeeded.” In his role of Project Leader, Ben was assisted by Hans van de Sande for the daily management and Kees Janse for supervising the welding work.

But in the meantime, additional work for the Royal Netherlands Navy had to be carried out. “The Rotterdam is a Landing Platform Dock (LPD), a ship whose rear section can be tilted back using ballast, so that the internal dock is filled with seawater”, adds Ben. “By sinking the stern in this way, the landing craft can sail into the dock and then from the ship into the sea. The landing craft driven by marines slid into the dock along a wood panelled wall, damaging the panelling.”

The rear tailgate of the vessel was too short for deployment in the former Yugoslavia, which meant that the stern had to be lengthened by three metres.

The rear tailgate of the vessel was too short for deployment in the former Yugoslavia, which meant that the stern had to be lengthened by three metres.

“In consultation with Henk Provoost from Engineering, we came up with a solution; we came up with the idea of replacing the wooden panelling with plastic panelling that could be safely attached to the wall using a special method. I remember that we were drawing construction details at the last minute. The panelling had to be about six centimetres thick, but we also had to take into account a significant expansion coefficient. The cladding therefore had to be fixed so that there was still some space between the plastic and the wall. After a meeting in The Hague on the way home, we had secured the assignment.”

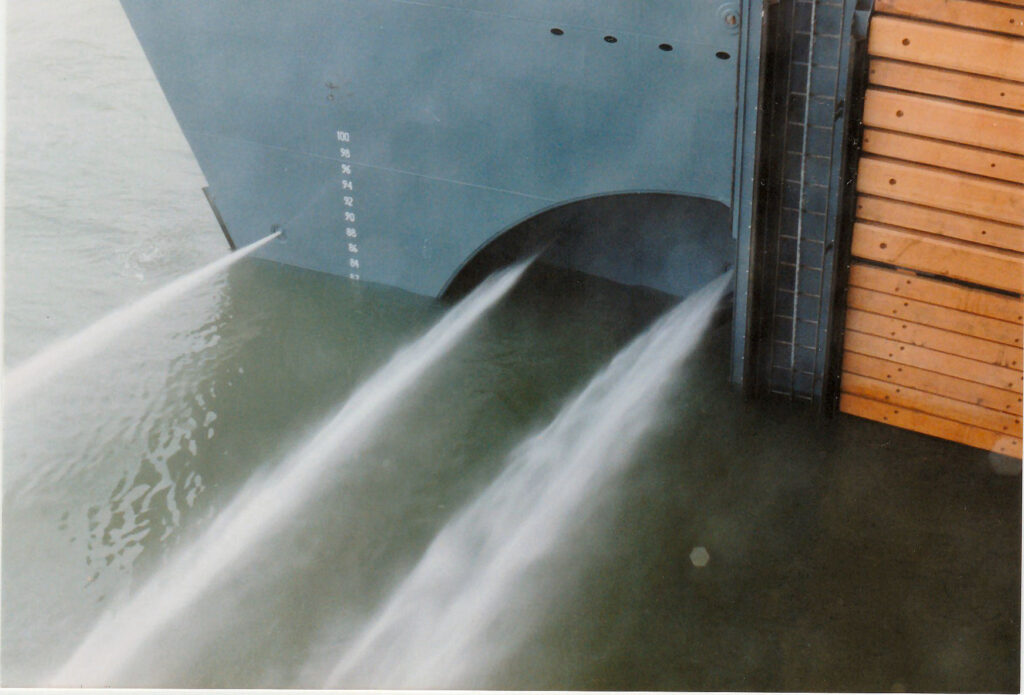

“In short, it was a period in which a lot was asked of our ingenuity and coming up with creative solutions to problems. Engineer Roel Sinke had designed underwater jets to keep the amphibious ships away from the edges when entering the flooded inner dock. He had been partly inspired by the wild water ride at the Efteling amusement park. He had made a test set-up at home and brought it to the yard. It only consisted of an aquarium tank, a plank with a sail as a boat, a table fan and an aquarium pump to simulate the underwater jet.”

Designed by Engineer Roel Sinke, the underwater jets keep the amphibious ships away from the edges when entering the flooded inner dock.

Designed by Engineer Roel Sinke, the underwater jets keep the amphibious ships away from the edges when entering the flooded inner dock.

“But of course, we also had a lot of calculations and documents to explain the methods.” This idea also earned ‘De Schelde’ an order. “The floor of the dock on board was also replaced. It was made of wood and was badly damaged. We asked two ‘Schelde’ men who had worked in the defunct carpentry workshop, and who were now doormen, to do the job. We hired tools, and these two carpenters, Jan Stroo and Willem Hollestelle, laid a completely new wooden floor in three days. That was great, very clever, but this duo also enjoyed the job because they were really doing their job again! They loved it.”

"This was a period in which a lot was asked of our ingenuity and coming up with creative solutions to problems." Ben Angel

The highlight of the urgent work on the HNLMS Rotterdam was the three-day modification of the tactical control centre on board, where plans are developed for amphibious landings all over the world. Ben: “The marines were not satisfied with the set-up in the room. Desks with computers were lined up like a train compartment. The Royal Netherlands Navy wanted to change that. In consultation with the marines and subcontractors, a simple but effective solution was found: the train layout was replaced by a round table. From then on, the commanders could sit there and give orders to the operational people at the control panels. The big advantage of such a round table is, of course, that you can look at each other.”

All this work on the Rotterdam was a real race against time, says Ben. “At a certain point, the ship was crawling with people to get it ready in time. We worked very hard. I remember that the then Minister of Defence Frank de Grave visited us at nine o’clock in the evening on the day we were finished. Two hours earlier, we had finished laying the floor in the renovated tactical headquarters. We received a letter of thanks from the then Commander of the Royal Netherlands Navy. But the cooperation with the Royal Netherlands Navy, despite the time pressure, was always excellent. It just clicked and the lines were short.”

"The highlight of the urgent work on the HNLMS Rotterdam was the three-day modification of the tactical control centre on board."

"The highlight of the urgent work on the HNLMS Rotterdam was the three-day modification of the tactical control centre on board."

“When the job was done, the HNLMS Rotterdam sailed to the outer harbour where the 166-metre long and 27-metre wide ship was fully equipped with landing craft, helicopters, bulldozers, vehicles and 600 marines. In the early morning of 15 April 1999, the LPD set sail for the Balkans. I sailed as far as Cherbourg, where I disembarked with six other people in a rubber boat and was taken to the quay. I had to let the seawater out of my Samsonite and I remember that we were quite a sight when we stripped off our wet clothes on the quay to put on dry clothes.”

Team Leader Mechanical Systems Cees Louwerse.

Team Leader Mechanical Systems Cees Louwerse.

Cees Louwerse was one of the approximately two hundred engineers who designed HNLMS Rotterdam (construction number 377). He was Team Leader Mechanical Systems. “I was responsible for the layout of the technical rooms with the related piping systems: the diesel generator rooms, pump rooms and propulsion rooms,” Cees recalls. “In those days we still drew at drawing boards. Yes, it was a challenging job. I remember that at the last minute we had to change the design of the propulsion from diesel direct to diesel electric. This made it easier for the ship to navigate slowly along the coast for long periods.”

The size of the ship also posed a challenge. “De Schelde had not built such an enormous ship in decades. The construction took place in ‘East’. In Hall 2, enormous ring modules were made to assemble the ship in the large covered dock. Beforehand, as much equipment and piping as possible was assembled in these modules. It was a construction method that was new to us. I remember that the ring modules were so heavy that the cranes lifting them were at the limit of their lifting capacity.”