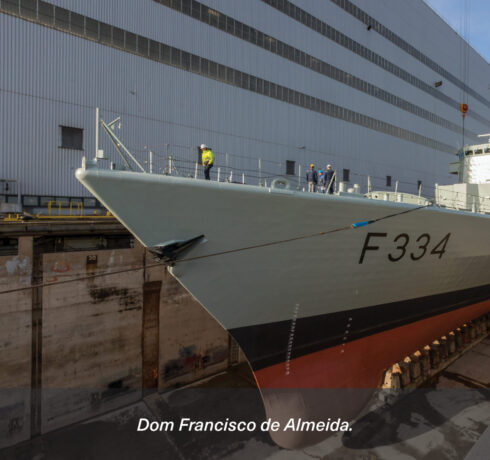

The Portuguese Navy’s M-class frigate NRP Dom Francisco de Almeida will soon be ready for many more years of service. The 27-year-old vessel underwent a comprehensive overhaul last year at Damen Shiprepair Vlissingen (DSV) as part of a Midlife Update (MLU). The frigate is once again in tip-top shape, and has sailed to the Rijkswerf in Den Helder for re-installation, and, if necessary, renewal of the communication and weapon systems under the supervision of the Dutch Naval Maintenance and Sustainment Agency. This work is taking place while DSV subcontractors are working on a number of remaining points, which will be completed in the course of February.

Project Manager Robin Juranek looks back on this substantial project with satisfaction. “Working on naval vessels is something that suits us very well,” he says. “And especially with this ship, which was built right around the corner, so to speak. Many of our employees have a special bond because they helped build it. If you compare a naval vessel to a car, we are the qualified dealer where the owner can have his asset serviced with peace of mind.” NRP Dom Francisco de Almeida is already the second De Schelde-built M frigate in a row that DSV has successfully refurbished. Sister ship NRP Bartolomeu Dias was in for an MLU earlier.

NRP Dom Francisco de Almeida is the second De Schelde-built M frigate in a row that DSV has successfully refurbished.

NRP Dom Francisco de Almeida is the second De Schelde-built M frigate in a row that DSV has successfully refurbished.

They worked on the ship in Vlissingen-Oost for over a year. Most of the work was carried out by subcontractors working under DSV. “I think more than eighty percent of the job was done with the help of subcontractors,” Robin recalls. At the end of January last year the ship arrived at DSV in Vlissingen-Oost. Eight weeks later, at the end of March, the frigate went into the covered dock. The former multipurpose frigate HNLMS Van Galen of the Karel Doorman class was then thoroughly overhauled and it is estimated that it will last another ten years or so.

The ship was completely repainted inside and out and many pipes and cables were replaced. “I think a total of about 60 kilometres of cables were pulled, especially for the sensors, weapon systems and communication equipment (SEWACO),” says Robin. “In addition, many of the pipes for the foam firefighting systems have been replaced. These pipes are only in the technical areas.” Due to Covid-19, it was a challenge to carry out all the work on schedule, as DSV was obliged to limit the number of people working at the same time in the same room.

"If you compare a naval vessel to a car, we are the qualified dealer where the owner can have his asset serviced with peace of mind.” Robin Juranek

Due to Covid-19, it was a challenge to carry out all the work on schedule, as DSV was obliged to limit the number of people working at the same time in the same room. Yet, says Robin, through clever planning this all went well. “We were able to carry out the work here in Vlissingen according to plan. The remaining points that our subcontractors are still finishing up in Den Helder will probably be ready in the course of February.”

That ‘after-care’ at the Rijkswerf is directed by Production Coordinator Patrick Brasser of DSV. “Certain work could only be done with fuel in the ship. When it was docked in Vlissingen there was no fuel in it, but now in Den Helder there is,” Patrick explains. “Connecting and commissioning the on-board central heating and the fuel separator, for example, we could not do without fuel and so could only start once the ship was at the Rijkswerf.”

NRP Dom Francisco de Almeida is the former multipurpose frigate HNLMS Van Galen of the Karel Doorman class.

NRP Dom Francisco de Almeida is the former multipurpose frigate HNLMS Van Galen of the Karel Doorman class.

NRP Dom Francisco de Almeida departed from Vlissingen-Oost for Den Helder on 22 November 2021. Placing the armament, sensors and communication equipment back on board will take until the end of this year. This is all done under the direction of the Dutch Naval Maintenance and Sustainment Agency in cooperation with the client, the Portuguese Navy.

In Den Helder, the Dutch Naval Maintenance and Sustainment Agency is also responsible for the maintenance of the cruising diesels, the ship’s main engines, a job that is done by specialists from Wärtsilä. Robin and Patrick look back on an instructive and extremely pleasant project, they both say. Robin: “There was an enormous involvement of all disciplines and it was also nice that the Budget department looked over our shoulders for a part of the project. We also learned a lot from the MLU on the sister ship of NRP Dom Francisco de Almeida, NRP Bartolomeu Dias, the former HNLMS Van Nes.”

Patrick adds: “But although they are two almost identical sister ships, of course the projects were certainly not identical.” The scope of the work on NRP Dom Francisco de Almeida included propeller and shaft work in addition to painting, cable and pipe work. The complete on-board ventilation system was also modernised and the engines were serviced. The spaces for reversed osmosis (RO), where seawater is turned into drinking water, were thoroughly renovated and a brand new chilled water maker was installed at the front and back of the ship.

NRP Dom Francisco de Almeida departed from Vlissingen-Oost for Den Helder on 22 November 2021.

NRP Dom Francisco de Almeida departed from Vlissingen-Oost for Den Helder on 22 November 2021.

All safety equipment, such as sprinklers, foam extinguishers and lifeboat cranes, has also been replaced or refurbished. The large amount of steel work was a big challenge, according to Robin and Patrick. While hydro-blasting the ship before giving it a new coat of paint, it was discovered that much more steel needed replacing than expected. “The steel scope ended up being an unexpected mega job, which put a bit of pressure on the planning. But that job, too, was eventually completed on time, partly because all those involved managed to change gear very quickly and smoothly,” says Robin.

In the meantime, Production Coordinator Patrick regularly travels from Vlissingen to Den Helder to oversee the completion of the remaining points. The quality control and the maintenance of the actuators of the most important valves of the various on-board systems also fall in this category. “As Production Coordinator you have to keep quite a few balls in the air at the same time, but it is a lot of fun,” says Patrick, who once started at De Schelde as a ship’s metal worker and who also helped building the former HNLMS Van Galen.

“And compared to the job on the first Portuguese frigate, we were even able to make huge improvements. Partly thanks to lessons learned, the number of remaining points that now have to be picked up at the Rijkswerf is considerably lower than for the ‘Dias’.” In addition to all the subcontractors, almost all of DSV’s permanent employees put their heart and soul into the Portuguese project in day and evening shifts. “Something had been done in every room of the ship,” says Robin. The result is impressive. “It has become a beautiful ship,” concludes Patrick with satisfaction.