The Combat Support Ship (CSS) currently under construction for the Royal Netherlands Navy at Damen Shipyards Galați will be equipped with five lifts supplied by Holland Marine Lifts (HML). The CSS is actually a prime example of the range of lifts that the company produces, says HML founder and managing director Emile van der Starre. “We are specialists in the design, production, installation and maintenance of internal ship lifts. We supply a broad scale of products from small to large. From a small lift capable of transporting hundreds of kilos up to our largest lift, suitable for transporting tens of thousands of kilos.”

This diversity of products can be seen in HML’s scope on the CSS. First on the list are two hydraulic cargo lifts, each able to transport up to 2,500kg. “These two lifts have two stops and three stops respectively, and are suitable for carrying palletised cargo. Furthermore, they are equipped with A60-certified fireproof doors,” explains Emile.

A60 certified fireproof lift doors are being used on the CSS.

A60 certified fireproof lift doors are being used on the CSS.

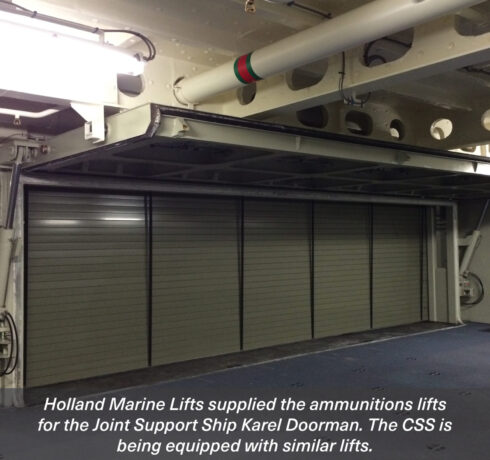

The next lifts are a small two-stop 300kg lift and a crew lift with five stops, which equates to “a total vertical lifting distance of 15 metres – that is substantial”, says Emile. The HML scope concludes with the CSS’ largest lift: a platform lift which will be used for munitions transport. “Measuring eight by three metres, this is one of our largest lifts, capable of transporting up to 12,000 kg.” Such sizeable dimensions mean that this lift can be loaded by forklift trucks. “And to provide the additional levels of safety required for munitions transport, this lift will have water-tight and gas-tight doors and explosion-proof electrical controls.”

Made-to-measure products

Like all of the lifts that HML has provided its customers in its twenty years of business, the CSS lifts are bespoke products. “We started in October 2002 – literally working out of an attic office room – and have grown into a company with 25 people.” HML is active in three main maritime sectors: naval, offshore and yachting. To this end, in addition to Damen Naval, HML counts Damen Yachting and Damen Shipyards Gorinchem as important clients. “After delivering our first 100 lifts, I thought I had seen everything. I thought that again after 200 lifts,” smiles Emile. “To date, HML has delivered more than 400 lifts – all have been made-to-measure products. Every project is different, for example, the lifts that we worked on for the JSS and the LPD are very different to the ones on the CSS. This is what makes our work enjoyable.”

HML Managing Director Emile van der Starre.

HML Managing Director Emile van der Starre.

Emile explains why HML’s lifts are not standard products: “As a lift manufacturer, we are often involved from the beginning of a project because quite often a lift shaft runs from the lower decks of a ship. We need to know about those lower decks, but of course also about what is happening, for example, five decks above. However, because the upper decks of a ship are often fully defined at a later stage, we often have to make changes to our product. This is the power of HML; we do all our engineering in-house which gives the flexibility that is so often required.”

The CSS project illustrates this flexibility, Emile goes on to say: “The design of the first four lifts went perfectly. The fifth one needed some adjustments; it was initially planned to be an electrically powered traction lift [acting with a counterweight], but we had to make some changes to supply a hydraulic lift.”

Project status

Four of the five HML lifts have been installed into the CSS in Romania; the fifth lift is scheduled to be installed in the next few months. The installation process is carried out by Damen’s own personnel, under supervision from one (sometimes two) HML engineers. “Because we get involved from the early stages of a project and are only finished when the ship is finished, a naval project such as the CSS is extensive, taking a number of years. Moreover, the amount of ILS-related documentation required has increased considerably over the years. Reflecting that, our relationship with Damen is intense, but also very pleasant.”