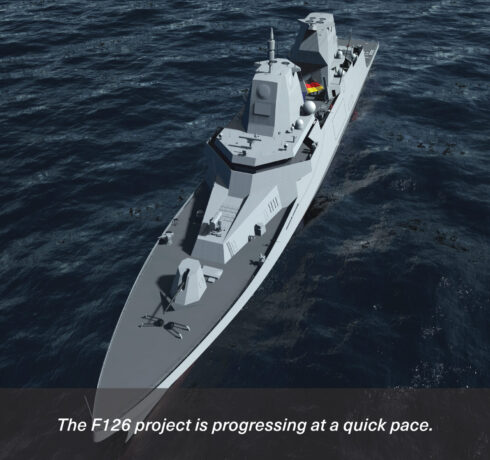

“Time is really starting to fly on the F126 project,” says Damen Naval’s F126 project director Frank Verhelst. “One particular way we are seeing this is the growing number of contracts we are securing with subcontractors.” Of the numerous supplier companies that Damen Naval has signed up to join the F126 team, three in particular stand out. The first is Rolls-Royce Power Systems, which will be supplying the automation solutions for the four F126 frigates for the German Navy. The automation systems will consist of an Integrated Platform Management System, and a Condition Monitoring System. Frank: “In fact, the Rolls-Royce and Damen engineering teams have already produced their preliminary design review, which is the first important milestone of this contract.”

The second key supplier that Damen Naval has contracted to the F126 project this year is Lockheed Martin. This long-established company will be producing and delivering two MK 41 Vertical Launching System modules for each of the four frigates. The most recent contract to have been signed was with Leonardo, which will be supplying their OTO 127/64 LightWeight Vulcano naval defence system, in addition to simulators for crew training, on-board system integration and commissioning.

"Visiting our partner yards gives us the chance to get to know our ‘building partners’ and to discuss topics such as material and information flows.” Frank Verhelst

These three contracts represent the continuation of some long-term business relationships for Damen Naval. “All these three companies have a long history with Damen Naval. For example, we worked with Rolls-Royce, Lockheed Martin, and Leonardo on numerous vessels. Furthermore, it is important to note that these suppliers are also familiar with the German Navy. This gives us a head start in terms of building relationships.”

Looking at the project’s engineering operations, the F126 team delivered the preliminary design review for the automation scope in March. “This marks an incredible effort from all involved as the contract with our subcontractor only became effective at the beginning of January,” Frank adds. Another notable event was the third design review regarding the weapons systems, which was held in Koblenz.

The land-based training scope also progressed with Damen Naval’s client approving the so-called ‘Raumbücher & Teilkonzepte’ in March. The following milestone on the horizon is the preliminary design review of the Marine Technical School and the Marine Operations School, together with Thales which is working on the test centre; these deliverables are scheduled for completion later this year.

The F126 project held a small steel-cutting ceremony at Vlissingen-Oost for an F126 shock test section. L-R: Sofie Bernaert (Damen Naval Teilprojektleiterin Fertigung), Martin Herzig (BAAINBw), Frank Verhelst (F126 Project Director), and Jack Teuben (Damen Naval Projectmanager Manufacturing Engineering).

The F126 project held a small steel-cutting ceremony at Vlissingen-Oost for an F126 shock test section. L-R: Sofie Bernaert (Damen Naval Teilprojektleiterin Fertigung), Martin Herzig (BAAINBw), Frank Verhelst (F126 Project Director), and Jack Teuben (Damen Naval Projectmanager Manufacturing Engineering).

The relaxation of coronavirus-related travel restrictions during the first quarter of 2022 meant that Damen’s client could visit facilities in Vlissingen to hold technical discussions with the engineering teams. It also provided Damen Naval’s team with multiple opportunities to visit key production locations in Germany. This is important because the F126 frigates are going to be built at three different locations: German Navy Yard Kiel, Peene Werft in Wolgast, and Blohm+Voss in Hamburg (all under the responsibility of Blohm+Voss). In February, members of the construction team were invited to German Navy Yard Kiel, where the fore-ships will be built. In March, the team visited Peene Werft in Wolgast, where the aft ships will be constructed.

Frank goes on to say that visiting the building yards at this early stage is vital. “Not only does it give us the chance to meet and get to know our ‘building partners’, it is also the opportune moment to discuss topics such as material and information flows. These visits were a great starting point in aligning our processes with our partner yards.”

While the visits to Germany will certainly be beneficial to the future progress of the project, it wasn’t the only interesting news to have happened recently. Frank: “On 24 March, we held a small steel-cutting ceremony at Vlissingen-Oost for an F126 shock test section. This will not be part of the final ship construction but was still a significant moment while the first production activities for the project are becoming visible.”