Wouter Witzel EuroValve is a leading global manufacturer of valves. The company, based in Losser, Overijssel, has supplied hundreds of electro-hydraulic butterfly valves for the new supply ship HNLMS Den Helder, which Damen Naval is building for the Royal Netherlands Navy. The cooperation with Damen Naval was excellent, says Justin Bijenhof, who is account manager at Wouter Witzel. “The contact was very open, clear and without any fuss. To us, Damen really was a competent technical partner from whom we learned a lot, while they also learned from us in a joint process towards an optimal product.”

Wouter Witzel has been in business since 1966, and manufactures around 250,000 valves every year.

Wouter Witzel has been in business since 1966, and manufactures around 250,000 valves every year.

Wouter Witzel signed the contract for the delivery of the valves in December 2020. The company’s scope was to supply the electro-hydraulically operated butterfly valves and other valves plus the associated drives (actuators) for the Den Helder. Many of them have already been installed in the ship. The valves with the Wouter Witzel signature can be found, for example, in the fire-fighting and extinguishing systems, on the helicopter deck, in the drinking water pipes, the drainage system for bilge and the cooling water system in the engine room.

Wouter Witzel account manager Justin Bijenhof.

Wouter Witzel account manager Justin Bijenhof.

The Overijssel-based company also made all the hull valves for the ballast water inlet and outlet system. “We delivered those hull valves in January last year, there were about one hundred and fifty of them,” says Justin. “At that time the hull had only just been built and the hull valves had to be put in straight away so they could continue with the construction. We delivered the last material for the new naval vessel last December.” Wouter Witzel has been in business since 1966. The company is located on the De Pol industrial estate in Losser near Enschede, where it manufactures around 250,000 valves every year.

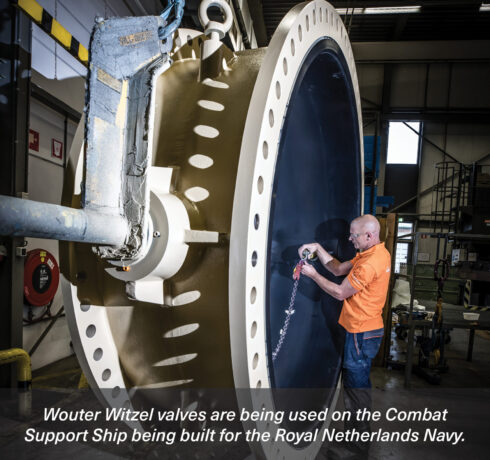

“We do everything ourselves,” Justin explains. “And all in one location: from design and development to delivery and testing of the valves. We are proud of that. So, you can say that we have supplied a Dutch product to a Dutch naval builder for a Dutch naval ship.” Laughing, he adds, “And then our valves are orange too…” Wouter Witzel’s raw frames and valve blades arrive at the company as castings, and are then extensively machined into a quality butterfly valves. The entire process, from turning, milling and vulcanisation (rubber coating) to testing and spraying, takes place in the large production halls in Losser. That is why some 250 people work there.

The entire process, from turning, milling and vulcanisation to testing and spraying, takes place in the large production halls.

The entire process, from turning, milling and vulcanisation to testing and spraying, takes place in the large production halls.

In Losser, they can make valves up to a diameter of no less than 2.2 metres. The smallest in the range has a diameter of only 40 millimetres. An enormously varied range, therefore, which has not gone unnoticed in the world. Wouter Witzel’s clientele includes major international players such as Maersk, Boskalis, Meyer Werft, IHC Merwede, Royal Caribbean International, Jan de Nul, Equinor, Shell and Fincantieri. “The Nederlandse Aardolie Maatschappij [a Dutch oil and gas exploration and production company] NAM, was our very first client back then,” Justin says.

“We do everything ourselves. And all in one location: from design and development to delivery and testing of the valves." Justin Bijenhof

“Nowadays, most of our customers come from the maritime sector, industry – for example, oil and gas companies, (petro)chemical plants and steel companies – and water companies from all over the world. Damen has been a good customer of ours for years. The valves we made for the new Navy supply ship, officially the Combat Support Ship (CSS) – have to meet very strict specifications, because on a military ship such material must be one hundred percent reliable at all times under all circumstances.”

In Losser, they can make valves up to a diameter of 2.2 metres. The smallest in the range has a diameter of 40 millimetres.

In Losser, they can make valves up to a diameter of 2.2 metres. The smallest in the range has a diameter of 40 millimetres.

“For example, if a valve on board has not been used for a long time, you must still be able to open it again in no time if you suddenly need it during a mission…. This means that, as a supplier, you have to deliver customised solutions. The Defence Materiel Organisation (DMO) will only purchase equipment for the Royal Netherlands Navy after thorough research and proven suitability. They look extremely closely at where and how it will be used on board. Because our company was not only the supplier but also the manufacturer of the valves for the CSS, we were able to think along with them in that process.”

“My role was to advise both DMO and Damen Naval in order to reach the best solutions together technically and commercially.” In 2005, Wouter Witzel EuroValve was acquired by the Danish AVK Group, “just like us, also a family business”, says Justin. Wouter Witzel hopes to work together with Damen, another family firm, on a regular basis in the future. “For the Den Helder, we had a very good and pleasant cooperation with the people of Damen Naval. A great client. It really went both ways. The cooperation back and forth was really worth its weight in gold.”