Damen Schelde Marine Services’ latest contract with Norwegian tanker operator Odfjell is not the first of its kind. “But it is definitely the biggest,” begins Jeroen Caris, Commercial Manager at DSMS. Jeroen describes the DSMS contractual scope as a “full package of after sales service – a plug-and-play solution for the client”. Based in Norway and established in 1914, Odfjell is a chemical tanker company that operates a fleet of 69 vessels from 13 offices around the world.

Although Odfjell has been a client of DSMS for close to ten years, this latest contract marks a step forward in the customer/contractor relationship. “We have had a strategic cooperation with Odfjell since 2016, keeping dedicated stock for them in our warehouses in the Netherlands, Shanghai and Singapore,” Jeroen goes on to say. “However, this has mainly concentrated on the larger engine parts such as cylinder liners.”

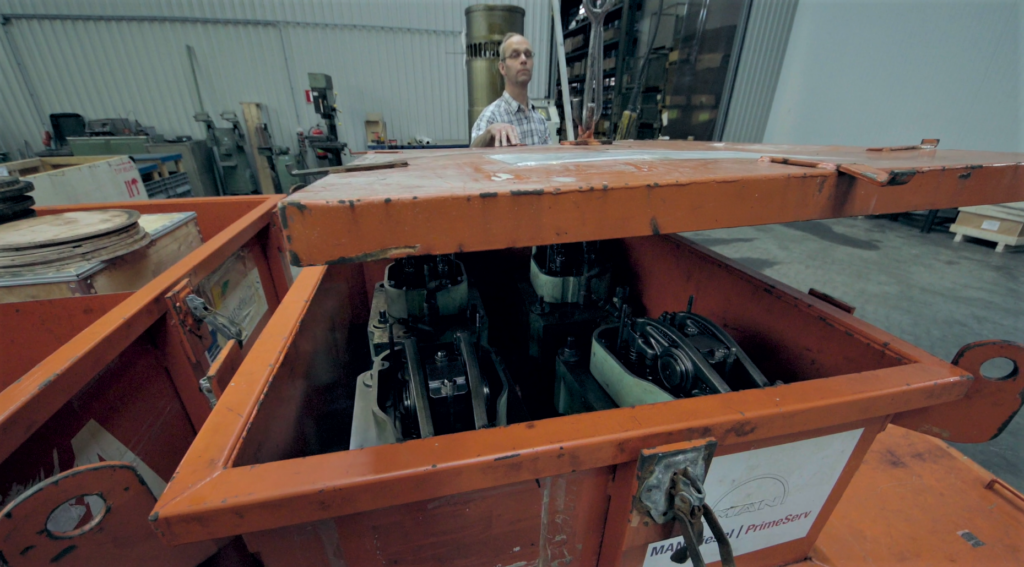

When the customer needs to carry out a generator overhaul on board, DSMS delivers a container full of parts and components.

When the customer needs to carry out a generator overhaul on board, DSMS delivers a container full of parts and components.

The latest contract, signed by the two parties in early June, is more extensive, meeting the needs of a complete overhaul of a ship’s generator. “We call it a ‘pit-stop’ arrangement,” says Jeroen. “When our client needs to carry out an overhaul of one of its onboard generators, we supply them with a container full of every part and component that their engineers need to do the job.”

The fact that the container contains all necessary parts is not the only reason Jeroen calls this a ‘plug-and-play’ solution. DSMS facilitates the entire process, from delivery logistics, inspections, reporting and inventory; all the way to picking up the container of used parts once the job is done. In fact, DSMS can deliver and pick-up the ‘pit-stop’ container to the port of Odfjell’s choice. It is common that DSMS will drop off a container at one port and then pick it up at the ship’s next port of call. This allows the ship’s engineers to carry out the maintenance during sailing, thus keeping ship downtime to an absolute minimum.

The contract between DSMS and Odfjell is for a two-year timeframe and encompasses 12-15 containers for various engine types.

The contract between DSMS and Odfjell is for a two-year timeframe and encompasses 12-15 containers for various engine types.

The contract between DSMS and Odfjell is for a two-year timeframe and encompasses 12-15 containers for various engine types. “We are very happy with this contract with such a well-known tanker company,” Jeroen continues. “As an independent supplier with contact to the complete supply chain, we can incorporate multiple brands within a contract like this. This is something that really is unique. Moreover, we are the only company that offers such a comprehensive scope of after sales service.”

DSMS is also pleased to point out the sustainability aspects of this ‘pit-stop’ service; the transport of just one container per generator overhaul to and from the vessel is very efficient. “Furthermore, the used parts come back to us for reconditioning, and then ultimately to be reused once again,” Jeroen adds.