With its latest contract, DSMS has officially entered a new market segment: taking on an engine maintenance project for a Scandinavian-owned cruise ship. DSMS will be performing a complete overhaul of a 16-cylinder Sulzer ZAV40S engine.

Josine Glerum.

Josine Glerum.

“For this contract, we are providing the full maintenance solution, including spare parts supply, service team deployment, logistics and transport, and reconditioning work in our workshop,” begins Josine Glerum, DSMS UK and Scandinavia Sales Manager. “The size of this project is not to be underestimated: we will need six trucks to transport all the parts to the workshop to perform the job.” The fact that the project involves a Sulzer engine is special, linking back to DSMS’ history of being a licensed Sulzer engine builder (although the Schelde never built the ZAV40s type of engine).

"Wherever possible, reconditioning will be prioritised over replacement. This reduces costs and is good from a sustainability point of view too." Josine Glerum

Expert Eyes (and Ears) on the Job

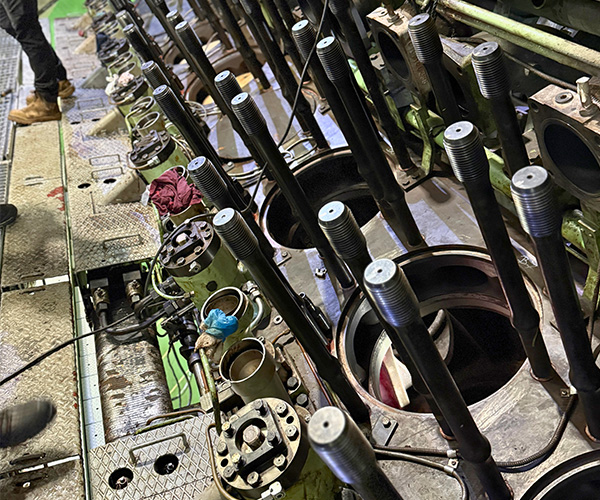

One of the most important first milestones of the project took place on 27 June. This was the pre-inspection of the engine and the engine room which took place on board the vessel. The purpose of the pre-inspection was to gain a practical oversight of the upcoming work by assessing the condition of the engine, reviewing previous performance reports, and, most important, meeting the ship’s engineering crew and fine-tuning the planning.

In addition to one of DSMS’ senior service engineers, Josine carried out the pre-inspection with an external consultant. “We have brought in a seasoned Sulzer ZAV40S specialist to support us during the most important phases of this project. He’s been working with ZAV40S engines for decades and has installed and maintained them on many vessels,” she adds.

DSMS tries to extend the lifetime of every component.

DSMS tries to extend the lifetime of every component.

“While most people rely on sensors and monitors nowadays, he still listens and feels the vibrations; he’s from the generation that can practically talk to the engine. In fact, the client’s chief engineer, who has worked with these engines for over 20 years, told us, ‘I’m curious to know if there’s a person on this planet who knows more about these engines than I do’. I am pleased to say that we are working with one! Of course, we fully trust the knowledge and expertise of our own service engineers, but it’s always good to bring in an external expert.”

Creativity & flexibility

The pre-inspection included gaining a clear picture of the logistical aspect of the project. “We have chosen to do all our reconditioning and maintenance work in our workshop: this will increase the overall efficiency and quality of the project. This means, of course, that we will need to dismantle the parts from the engine and disassemble the parts – cylinder heads, pistons en connecting rods, cylinder liners, and fuel pumps – in our workshop.”

Considering the number and weight of the components – just one cylinder head weighs 1,000 kilos – getting everything out of the engine room will be a challenge that calls for creativity, flexibility and a sharp eye for safety. Josine: “That’s why we also inspected the vessel’s cranes and coordinated closely with the ship’s crew.”

Sustainable Engineering

DSMS intends to do the overhaul and maintenance work when the vessel is at sea. The project is scheduled for completion in early autumn. “Every part will be cleaned and inspected, and the client receives full reporting on the status,” Josine notes. “We will try to extend the lifetime of every component; wherever possible, reconditioning will be prioritised over replacement. This reduces costs and is good from a sustainability point of view too. So-called consumables will be replaced, but parts such as cylinder heads can be reconditioned multiple times.”

One of the reasons for the pre-inspection was to assess the condition of the engine.

One of the reasons for the pre-inspection was to assess the condition of the engine.

“A nice way to start a project.”

Looking ahead to the execution of the project, Josine says: “We’re really looking forward to working on a cruise ship: a new maritime segment for us. The pre-inspection went well, the ship’s crew is motivated, and the collaboration is strong. It’s a nice way to start a project. And, on a personal level, going on board and seeing the engine room firsthand has been incredibly useful. It gives you a true sense of the logistical challenges and what’s needed to make a project like this succeed.”

There is one final aspect of this contract that Josine wants to mention. “Our scope of work on this contract is just one ZAV40S engine on one ship. But this client has two vessels, each with five identical engines. If this pilot project goes well, there is potential for significant expansion.”

Besides this ZAV40S project, DSMS is working on several others with a similar setup, involving the supply of new spares, reconditioning parts in the workshop, and performing overhauls on board. Coincidentally, one of them is also a ZAV40S project taking place in Singapore!