It has no office, no staff and no director, but Cooperative Research Ships (CRS) has been thriving for more than half a century. The international research network was founded in 1969 with the main objective of carrying out research projects that enabled the international shipbuilding industry to design even better ships. What is special is that within the CRS, competing shipyards sit together at the research table, says Oscar van Straten, who represents Damen Naval within the international think tank.

Damen Shipyards Group has been a member of CRS since late 2007, says Oscar, who in everyday life is Lead Engineer Hydrodynamics at Damen Naval’s Research & Technology Support department. “Damen pays 65,000 euros per year in membership fees to CRS. All other parties within this partnership – 24 in total – each pay the same annual amount. If you add all of that together, you arrive at an amount with which you can do great things in the field of research.” CRS was established 52 years ago by MARIN in cooperation with a number of shipyards, oil companies and classification societies.

Oscar van Straaten represents Damen Naval at CRS.

Oscar van Straaten represents Damen Naval at CRS.

“The trigger was the fact that MARIN actually received the same questions from the shipbuilding industry over and over again from different yards on how they could design better ships,” Oscar explains. “At the time, these questions were mainly about building large oil tankers. The idea behind the CRS was that it was better to form a joint think tank than to work on ideas separately.” We are now over fifty years on. CRS celebrated its half-century in 2019 and has successfully undertaken many research projects over the years, projects whose results are publicly available to each individual CRS member.

Oscar: “The research projects focus on subjects like hydrodynamics, one of the pillars of CRS’ activities. This is the question of how to design a ship in such a way that it needs to dip, heave, sway and yaw as little as possible when there are high waves, so that a naval vessel, for example, remains optimally deployable despite all the swell and therefore suffers as little as possible from the high waves. Because you are more affected by all the acceleration levels in a place on one ship than another, you have to take that into account when designing the ship.”

The CRS logo.

The CRS logo.

He continues: “So as a shipbuilder you look carefully at where you locate the galley, command centre or bridge, because of course you don’t want crew members to turn green and yellow with seasickness during a heavy storm and therefore no longer be able to act adequately when they are chasing a boat carrying drug smugglers. One of the studies currently underway at CRS is a study into the installation of stabilising fins under ships that can be controlled from the bridge with the aim to reduce the sway of a ship in a storm.”

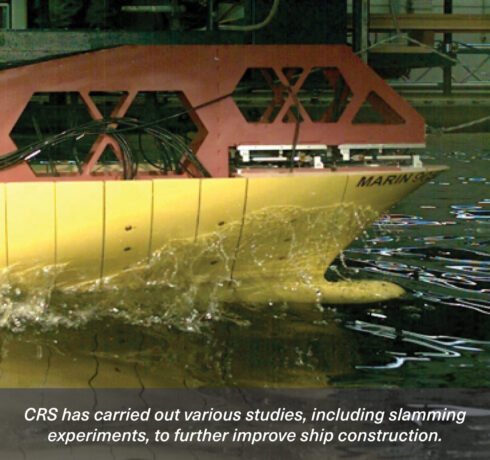

CRS also studied how to design and construct a ship that can best withstand the forces that the wave action exerts on the steel and the construction, the fatigue load. In addition, the CRS specialists are looking at how to construct ships so that they manoeuvre as smoothly as possible, and how to minimise the cavitation of the propeller. During cavitation, vapour bubbles form near the blade tip and edges of a propeller blade, which can implode. “If a ship’s propeller cavitates a lot, it is like hitting the propeller material with a hammer. This causes noise on board and, in the long run, propeller material can even be chipped away.”

"The idea behind the CRS was that it was better to form a joint think tank than to work on ideas separately.” Oscar van Straaten

About ten to twelve research projects are running simultaneously at CRS every year. These often result in computer programmes with which calculations can be made to optimise ship designs. The remarkable thing is that competing European shipyards work together on these research projects. The British BAE Systems, the French Naval Group, the Italian Fincantieri and the Spanish Navantia are competitors of Damen Naval, but within the projects of CRS, the companies all work closely together. “That is quite unique, all the more so because our members are also allowed to use the study results together.”

Currently, MARIN, seven major shipyards including Damen Shipyards Group, the Defence Materiel Organisation (DMO), the Germany Navy (BAAINBw) and, among others, Canada, the US Coast Guard, a number of research institutes, four major classification societies (American Bureau of Shipping, DNV, Lloyd’s Register and Bureau Veritas) and three propeller suppliers are members of CRS. Recently, an Australian party has also joined. “Because of the participation of DMO – the design office of the Dutch Royal Navy, Damen Naval is therefore doing joint research in the field of hydrodynamics with our largest customer,” Oscar says.

CRS members visit MARIN's Depressurised Wave Basin in Ede, The Netherlands.

CRS members visit MARIN's Depressurised Wave Basin in Ede, The Netherlands.

“And we therefore also have access to the same calculation tools that are developed within CRS.” The 24 CRS members meet annually towards the end of the year at an Annual General Meeting to review internal project proposals for consideration for implementation the following year. The simple principle is that the ideas that get the most votes get implemented, Oscar explains. Due to the coronavirus pandemic, the CRS annual meetings of 2020 and 2021 were online. The working group meetings for ongoing projects that take place throughout the year also had to take place virtually by necessity.

“Necessary, but very unfortunate,” concludes Oscar. “What you miss with such an online meeting is the small talk with colleagues from your field, which often takes place in the corridors. That is where you sometimes pick up unexpected useful information that you don’t hear during the official part of the meeting. These conversations in the margins make meetings on location extra fun. It is unfortunate that we have had to miss out on these conversations. In the end, Damen Naval’s participation in CRS provides a lot of useful knowledge, often in the form of new or improved calculation models, which can often be directly applied during the design and engineering of our ships.”

Anyone who wants to know more about Cooperative Research Ships can also visit the website: www.crships.org.